Challenges in power line inspection today

For many utilities, power line inspections still take place on foot. This method of inspection is very time-consuming, given that there are over a million local distribution lines. Using the human eye to collect visual data can take 1 year or more, even with a team of hundreds of people working constantly and are prone to human error.

The job is dangerous since it requires inspectors to get a close look at everything they need, including binoculars, rope access (climbing and rappelling), scaffolding, and cranes. When inspectors stand on scaffolding or cranes, they are exposed to the elements, which can occasionally exacerbate the risk of a fall.

Forward-thinking grid operators use manned helicopters equipped with high-resolution cameras for data collection. However, this is too expensive and difficult to scale up. The average contract cost of a helicopter power line inspection is statistically more than $4,000 per day, not counting the high maintenance costs.

Benefits of using drones for power line inspection

Drones are an attractive alternative for power line inspection. Here are the potential benefits of using a drone:

Increased safety

Traditional power line inspections require inspectors to stand on scaffolding and cranes and use rope access to climb on poles. Drone surveying for the power grid eliminates the need to put people in harm's way, and line workers can safely remain on the ground while the drone operator assesses the line.

Reduced work time and labor costs

Traditional methods require a team of experienced linemen to visually inspect all lines in an area to evaluate the lines for any damage or potential problems. Drone inspection reduces man-hours and labor costs by automating inspections with low maintenance costs, saving approximately 30 to 50% of money and time.

Access to hard-to-reach areas

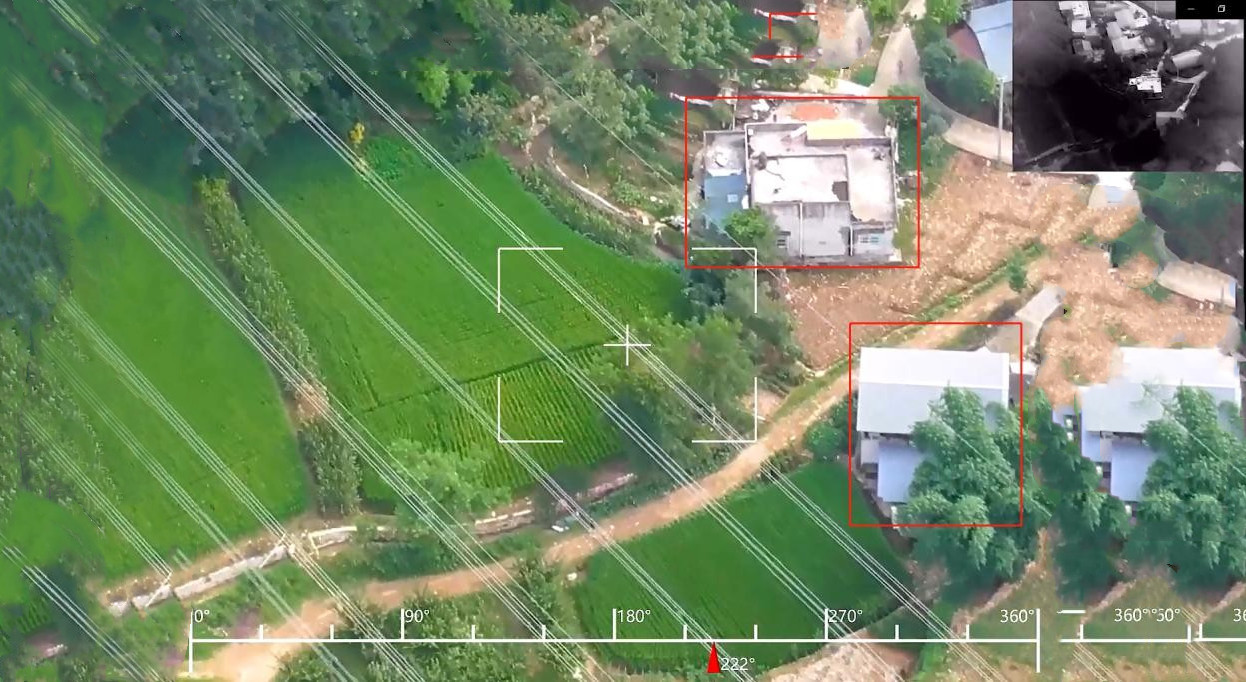

Drones are used to monitor vegetation encroachment along power lines, especially in hard-to-reach areas. Capable of navigating between dense trees, as well as taking off and landing in tight places.

More accurate data

Drones make it easy to fly along power lines and then take high-quality video and pictures, and inspectors are able to collect better, more detailed data than they would be using traditional methods.

Reduced complexity

Drones reduce the number of personnel and ancillary equipment that must be on-site to conduct inspections, significantly reducing the overall complexity of the project.

How drones are used in power line inspection?

A drone is so versatile, that it can be used to inspect power lines and power pylons for bird's nests, lightning strikes, rust/corrosion, and damaged bolts.

Vegetation management

Determine the distance of vegetation from power lines. This information can then be used to create a plan for which vegetation needs to be cut immediately so as not to interfere with the use of the lines.

Powerline corridors inspection

Drones conduct frequent, on-demand inspections to monitor the safety, reliability, and integrity of wires to improve efficiency and eliminate risk.

Fault inspection

Use drones to capture the status of the grid from multiple angles to reveal any faults or defects and address them in a timely manner.

Wildfire inspection

Use drones equipped with radiant heat sensors to obtain real-time temperature readings of power lines to immediately identify anomalies and avoid the risk of wildfires. At the same time, drone surveillance can monitor damage to power lines from hill fires caused by natural disasters, ensuring the safe operation of the power grid.

What kind of maps can you expect from a power line inspection drone?

3D Model

Commercial drones shoot over powerlines to obtain oblique imagery, which is then composited by third-party tools to generate 3D models. It can be used to calculate the height of the powerline and the ground, the distance from the powerline to the nearest obstacle, distance from the tower to another.

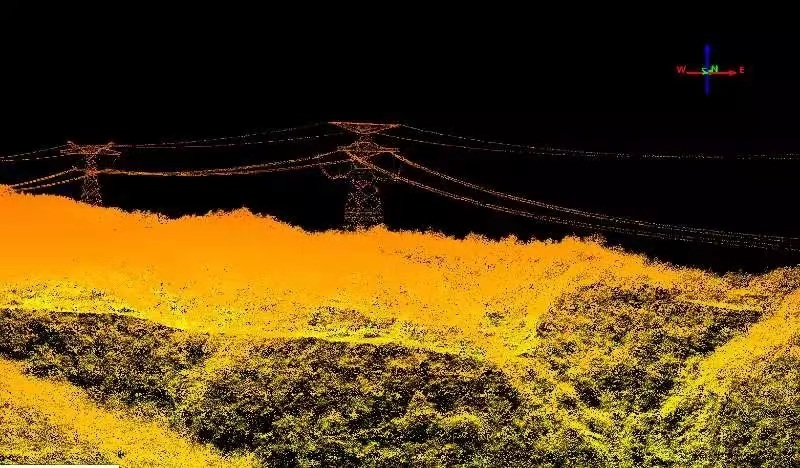

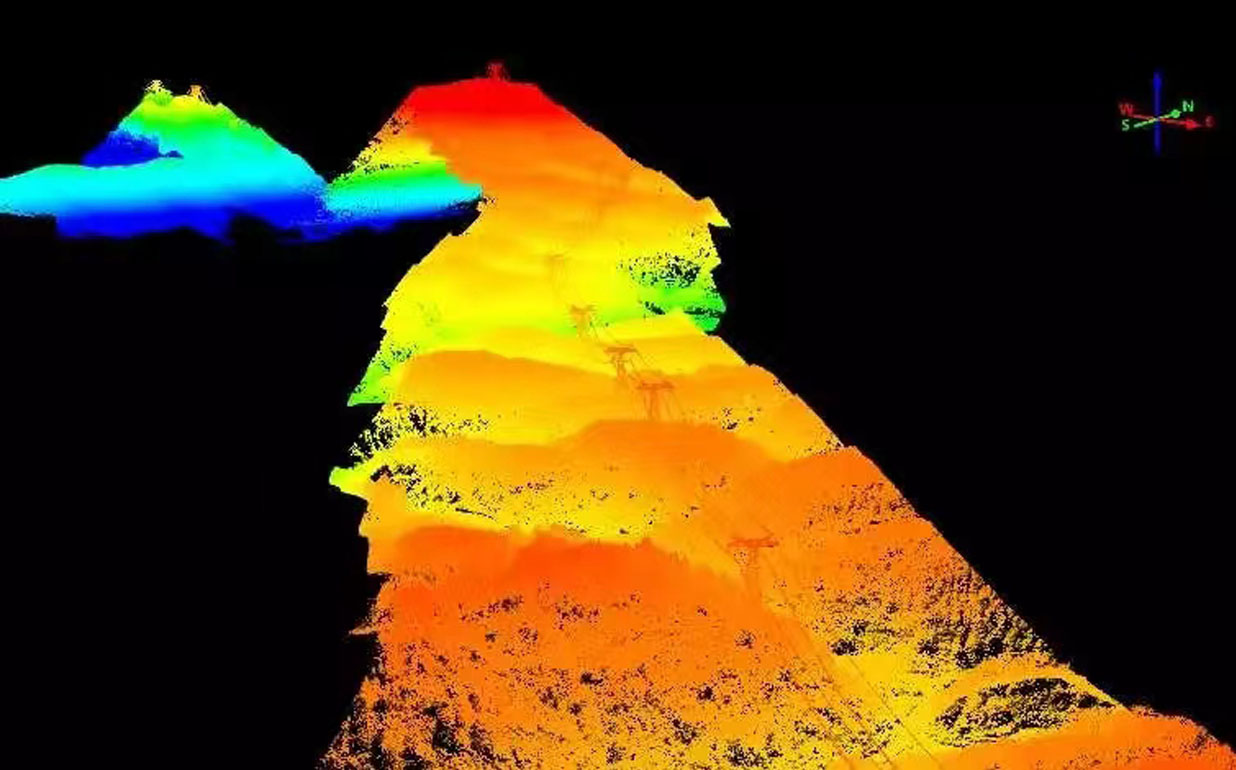

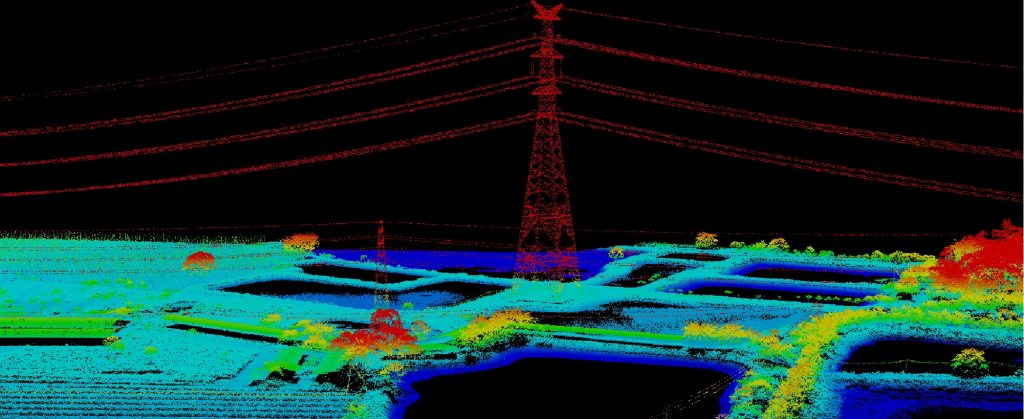

3D point cloud

After acquiring the spatial coordinates of each sampled point on the surface of an object, a collection of points is obtained by a LiDAR drone, which is called a "Point Cloud". The point cloud is obtained by combining laser measurement and photogrammetry principles, including three-dimensional coordinates (XYZ), laser reflection intensity (Intensity), and color information (RGB). It can be used for powerline 3D visual management, powerline route planning, and designing.

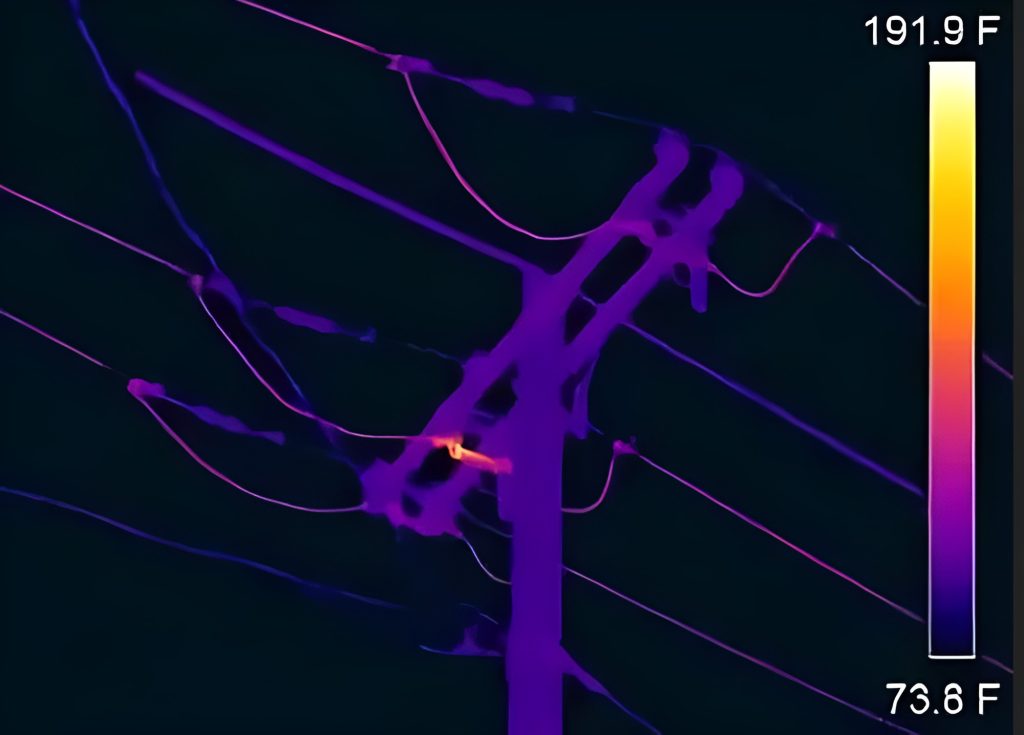

Thermal map

A thermal drone can be used for measuring the heat emitted from powerlines in order to analyze the abnormal voltage and contact resistance. It helps the operation and maintenance personnel to check the defects in time.

What is the best drone for power line inspection?

JOUAV is a reliable drone manufacturer and solution provider. JOUAV drones are easy to operate and enable inspection teams to obtain high-quality data with basic training while standardizing data output and streamlining the process. Here are some key features:

Payload Capability

JOUAV drones can carry a variety of equipment, making them perfect for power line inspections. They can be fitted with high-resolution oblique cameras, thermal imaging sensors, and LiDAR systems.

This means you can get detailed visual assessments, spot thermal anomalies, and create accurate 3D maps of power infrastructure all in one go.

By combining multiple sensor types on a single drone, you reduce the need for multiple flights, saving time and boosting efficiency.

Zoom Capability

When inspecting power lines, having a camera with zoom capability is crucial. JOUAV drones come with cameras offering 30x or 50x optical zoom, which lets you capture detailed images from a safe distance.

This is important because flying too close to power lines can disrupt the drone’s signal and pose safety risks. The zoom feature ensures you get high-quality images without compromising safety.

Anti-magnetic interference

Power lines generate strong electromagnetic fields that can interfere with drone operations. JOUAV drones are equipped with advanced technology to resist this magnetic interference, ensuring stable flight and accurate navigation.

This feature is especially important when inspecting power lines in areas with high electromagnetic interference, as it enhances reliability and safety.

Safe obstacle avoidance

Safety is a top priority, and JOUAV drones are designed with forward-looking and downward-looking millimeter-wave radar to detect obstacles up to 240 meters away.

The intelligent obstacle avoidance algorithms allow the drone to automatically adjust its flight path to avoid collisions. This system ensures smooth and safe inspections, even in complex environments.

Suitable for corridor mapping

JOUAV drones boast longer flight times, extending the range between battery changes. This is particularly advantageous for covering long, narrow stretches quickly and efficiently.

A single flight of CW-15 can cover 18-24 kilometers, making it possible to inspect extensive sections of power lines without frequent interruptions for battery replacement. Longer flight times translate to increased productivity and reduced operational costs.

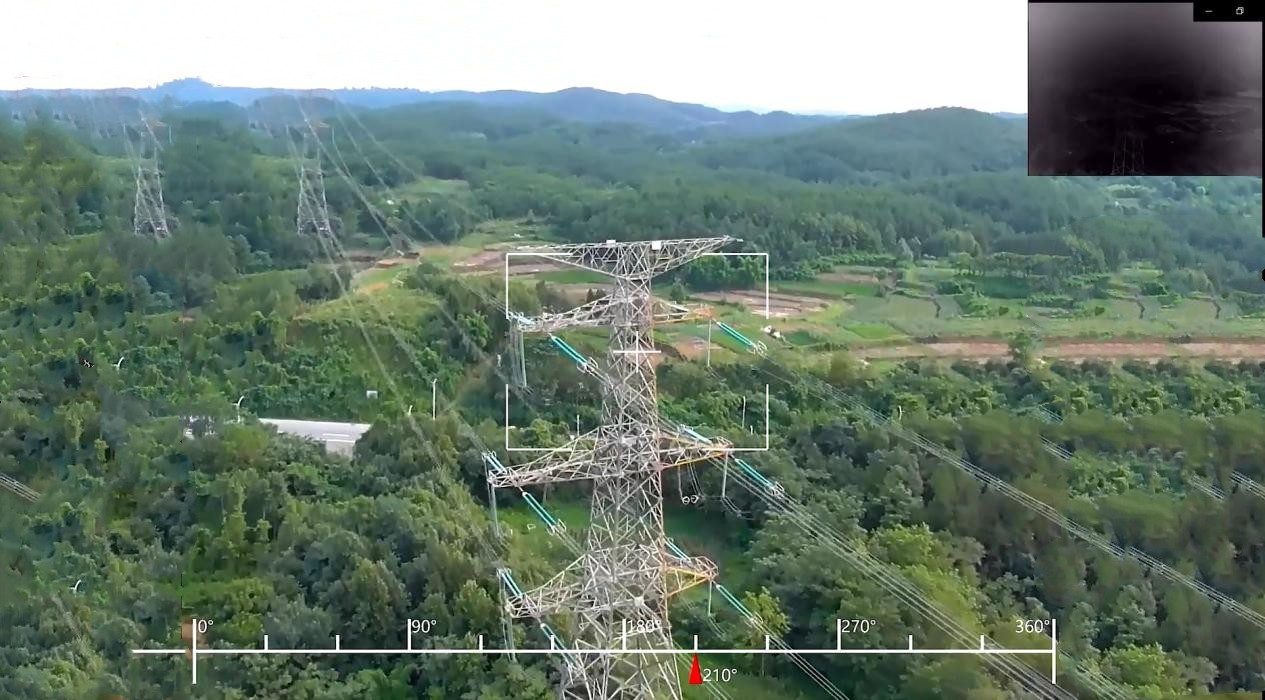

AI defect recognition and AR overlay

JOUAV drones use advanced sensors and AI to recognize objects and potential hazards along power lines in real time. They can overlay augmented reality (AR) elements on the live video feed, highlighting critical areas in red and less urgent ones in yellow.

This helps inspectors quickly identify and prioritize issues, making the inspection process more efficient and effective.

Cloud-based processing

JOUAV drones support live LTE streaming, which means inspection data can be transmitted in real time to a cloud-based platform called Jocloud. This platform provides tools for data storage, analysis, and management, allowing inspectors to view and analyze results immediately.

Cloud-based processing improves decision-making by providing timely and accurate data, streamlining the entire inspection process.

Real drone application in power line inspection

JOUAV drones have years of experience in operating drones for power line inspection. Drones have been used for inspections in all sorts of environments and conditions. See the following JOUAV case studies of power line inspection:

Wildfire patrol for the State Grid of Zhejiang

In April, the State Grid of China Zhejiang Electric Power Co., located in one of China's eastern coastal provinces, used a JOUAV CW-15 drone to inspect electrical infrastructure in high-risk fire areas.

"The biggest advantage of the JOUAV UAV is its efficiency. Mapping the same road two years ago, we used another drone, covering 3km of road per day, Right now, at that same time, we cover 872.83 km and 1,659 towers with JOUAV in three days". Andy Wang said, manager of the State Grid of China Zhejiang Electric Power Co.

Power line inspection for the State Grid of Guangxi

The State Grid of China Guangxi Co., a southern coastal city in China, recently used the JOUAV CW-15 to inspect 20 kilometers of power lines. The terrain for this inspection was predominantly mountainous and hilly, and the flight weather was light rain. Power line inspection for the State Grid of Guangxi The State Grid of China Guangxi Co., a southern coastal city in China, recently used the JOUAV CW-15 to inspect 20 kilometers of power lines. The terrain for this inspection was predominantly mountainous and hilly, and the flight weather was light rain.

"What I found about the JOUAV is that it is very easy to use because it is a complete system," said James Liu, inspection team leader for The State Grid of China Guangxi Co." The software is provided with the drone and integrated with the camera and PPK. You don't need to measure any offsets between the GPS and the camera yourself."

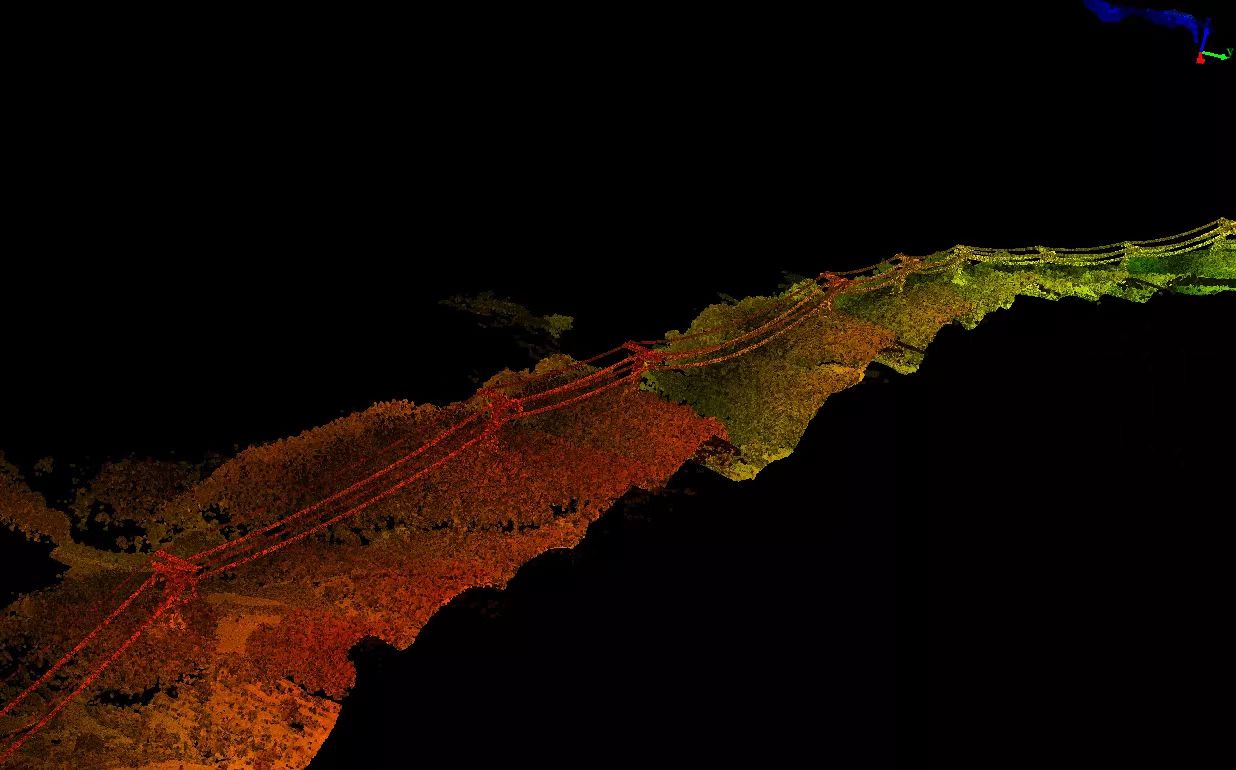

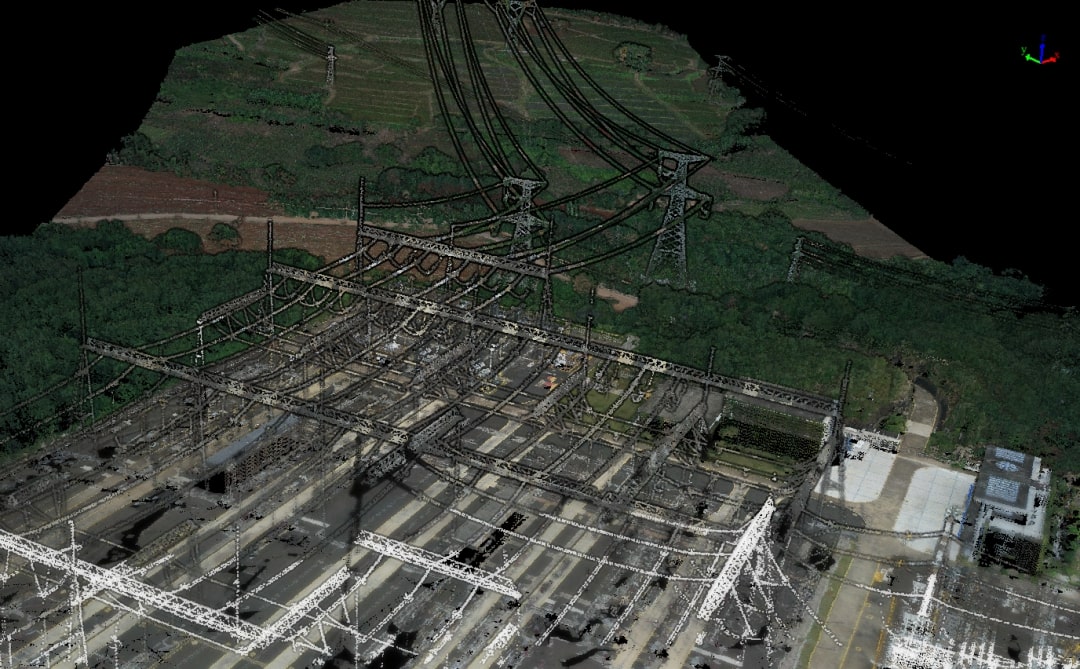

Power corridor inspection for China Southern Power Grid

In June 2020, China Southern Power Grid completed and put into operation the Yunnan-Guizhou interconnection channel project, which is a transmission corridor connecting Yunnan, Guizhou, and Guangzhou provinces with a total length of 1283 km. In June 2022, the company selected JOUAV CW-25E to carry JoLiDAR-LR22S in a pilot project to test and demonstrate the possibility of UAV inspection. Sections 642# and 877# were chosen as test sites because of their high mountainous terrain, with a total length of 52 km of power lines.

The CW-25E LiDAR system scanned a total of 52 km of lines(the entire line including the power plants at both ends of the road) and 142 towers in just 2 hours. After uploading the 33.7G of raw point cloud data collected during the inspection flight to JoLiDAR, LiDAR analysts from Southern Power Grid began processing it. It took 6 minutes to download the data and 50 minutes to generate the point cloud data. The average point cloud density was 38 points/m² and the highest point density reached 70 points/m².

- Read the full story here: Inspecting 52km of Powerlines for China Southern Power Grid in 2hrs

Autonomous powerline inspection in Guangdong rural area

In Panyu, Guangzhou, the Panyu power substation has significantly improved its operational efficiency using the JOUAV VTOL Hangar with an MG-120E EO/IR gimbal camera. Manual inspections of rural powerlines previously consumed 160 man-hours per 100 km. Now, with the hangar, operators control an autonomous UAV from the substation office.

This advanced capability not only expedites the inspection process but also significantly enhances safety by eliminating the need to dispatch personnel for manual inspections. As the team leader of the maintenance department aptly summarizes, "We use a thermal camera on the drone; if the power cable is worn out, the temperature will be abnormal, we will see it through the drone camera; it’s safer than sending a person to check it by hand."

Best drone software for power line inspection

FlightSurv is an easy-to-use surveying software that can be used effectively by beginners and advanced users alike. This 3D modeling and mapping software can be used as a mobile application for a single person or corporate clients with any number of users.

There are many autonomous flight features and options within the software, including generating and viewing a 2D map of the area on the fly. You can also perform several types of field data analysis before returning to the office, and upload your images to create high-resolution 3D maps in several different formats that can be shared with your entire team or customers.

Orthographic camera: powerline corridors inspection

The CA-103 full-frame aerial camera is the best RGB camera for power corridor inspection. It has a 61-megapixel full-frame Exmor R CMOS back-illuminated image sensor and JAL-35 lens for high image quality, nearly twofold sensitivity, and low noise. Specifically designed for the JOUAV drones, CA-103 Aerial Camera's vibration dampening plate uses four-corner protection technology to greatly improve the stability and accuracy of the drone when taking pictures.

Gimbal camera: Fixed point and detailed inspection

MG-120 Gimbal Camera is a light and small HD gimbal camera developed by JOUAV. The camera integrates infrared sensors and optical sensors at the same time, which can be used for detailed inspection and abnormal point troubleshooting. Its 30x optical zoom sensor allows you to see objects in detail up to 2km. With the 640*512 infrared sensor, the MG-120 can detect and identify tiny anomalies in power lines at night or in low visibility.

LiDAR: powerline inspection and accurate analysis

JoLiDAR is integrated with GNSS INS to produce accurate position and orientation data. Equipped with a fiber optic inertial navigation system, JoLiDAR-LR is more stable, more anti-jamming, and more accurate with higher data accuracy than other LiDAR scanners. In addition, JoLiDAR-LR has a 3X higher point cloud density than other LiDAR sensors. The higher the number of measured points gathered by JoLiDAR-LR power line inspection, the more information it is possible to get out of the 3D model created in the end. What's more, JoLiDAR-LR can be quickly sorted to form an intelligent workflow, with fast processing speed and simple results production process.

Feel free to contact JOUAV. What we can help you: