Inspecting 8,200 km of Pipeline with CW-25E VTOL in China

Inner Mongolia Western Natural Gas Co., Ltd. (IMWNGC) is a Chinese energy company that specializes in producing and selling natural gas. Founded in 2005, the company is headquartered in Hohhot, Inner Mongolia Autonomous Region, China.

Recently, one of the natural gas pipelines operated by IMWNGC posed significant safety risks due to the construction of the airport expressway. As a result, regular inspections were necessary, covering 467 km of the pipeline every five months. The inspection included pipeline inspection, high-consequence area inspection, and critical flood control point inspection.

Why did IMWNGC choose the JOUAV pipeline inspection solution?

IMWNGC previously used helicopters to inspect pipeline details such as cracks or corrosion, and encroachment of pipeline right-of-way (ROW). However, the operating costs for manned flights were high, including fuel and maintenance expenses, with an average cost of $150,000 per inspection. Conducting regular inspections every five months was nearly impossible.

To save costs, the company began exploring unmanned aerial vehicle (UAV) technology. They noted that UAVs had been successfully used in industrial inspections in China, and some of their peers had already used UAVs for inspections. The company hoped to use UAVs to increase the efficiency of pipeline inspections, reduce the cost of inspections, reduce the workload and risk of manual inspections, and improve their information management level through UAV use.

"When we conducted market research initiatives, we already knew that JOUAV's VTOL drones are well-known for their quality and reliability. Their vertical takeoff and landing capability, large coverage, and long range are designed specifically for pipeline inspections," said Eric, Project Manager of IMWNGC. "Moreover, UAV pipeline inspections are a long-term and continuous improvement work, which requires suppliers to be familiar with our work content. JOUAV has previously collaborated with many of our oil and gas pipeline peers, and their technical team has rich experience in the industry."

Eventually, they decided to use the JOUAV pipeline inspection solution, which includes a CW-25E VTOL drone, a CA-103 aerial camera, an MG-120E gimbal camera, and the JoCloud management platform.

How did the JOUAV pipeline inspection solution work?

IMWNGC established a drone inspection team consisting of seven people, who underwent formal training from JOUAV on how to use UAVs. Their mission is to use UAVs to inspect various facilities along the 467 km natural gas pipeline, activities within a 200 m range on either side of the pipeline that may cause damage to underground pipelines, such as construction projects, excavation work, or geological hazards such as floods and landslides.

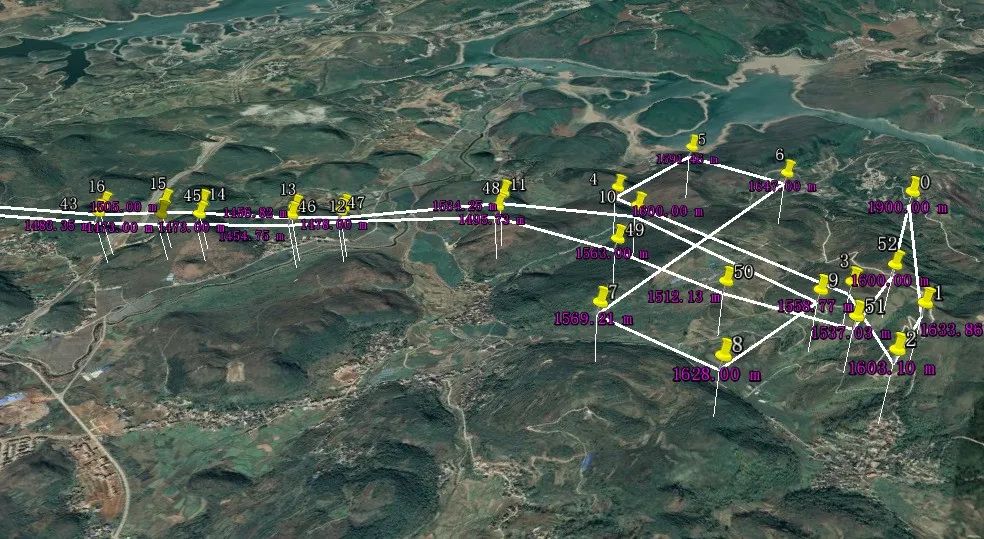

To design the route, takeoff, and landing locations for all CW-25E missions, they used JoCloud based on the coordinates and elevation data of the pipeline. "During the UAV mission, JOUAV technicians work on-site with our inspection personnel, resolving any issues that arise in real-time", said Li Wei, Leader of the IMWNGC drone team.

The flight route of the CW-25E for the inspection of the IMWNGC pipeline

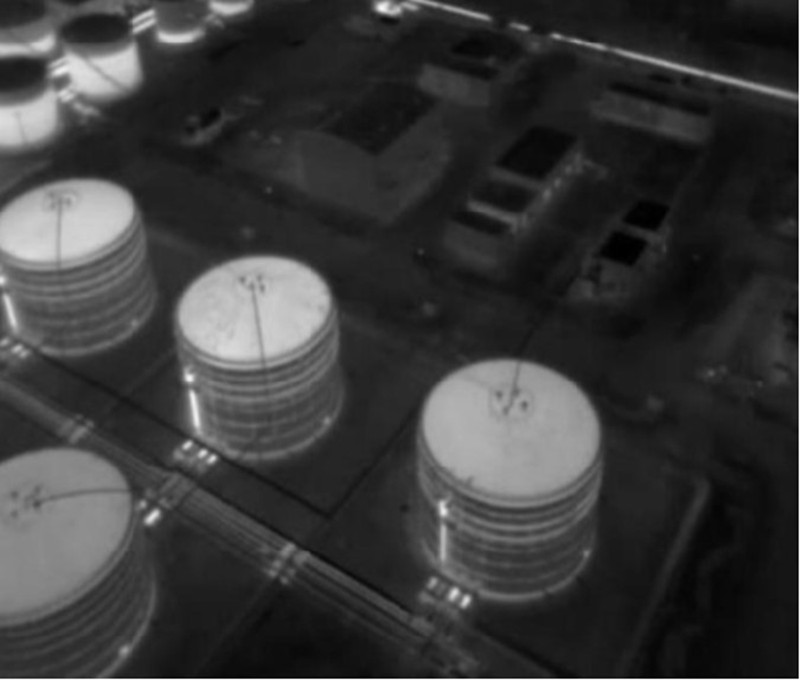

With the CW-25E and 61MP CA-103 full-frame cameras, the IMWNGC drone team conducted periodic pipeline inspections. They imported the photos, POS, and other relevant data into our drone inspection system, enabling them to quickly and efficiently identify potential security threats, such as third-party construction along the pipeline. This information is automatically pushed to the relevant management and patrol personnel through JoCloud.

The IMWNGC's inspectors then went to the scene to deal with the situation according to the early warning and then uploaded the results to the JoCloud cloud platform. This enabled IMWNGC to create a standard inspection report, which ensured that each inspection operation formed a closed loop of disposal.

The CW-25E carried 3-4 flights daily, covering over 400 kilometers of pipelines while capturing images and collecting data. In total, the mission has covered 8,200 kilometers and detected 287 warning events. The operation and maintenance department was promptly notified of all events, and proper measures were taken to resolve each issue.

Benefits of the CW-25E VTOL drone

The CW-25E VTOL drone offers several benefits that make it ideal for inspecting oil and gas pipelines, even in complex terrain.

"Thanks to the strong obstacle avoidance and vertical takeoff and landing capabilities, the CW-25E can fly autonomously in remote locations and capture valuable data for our pipeline inspections," said Li Wei.

Furthermore, the CW-25E is functionally scalable, making it a versatile tool for various missions. The Inner Mongolia Western Gas Company plans to equip the drone with a dual-light camera and an aerial shouting system. This will enable the UAV to capture both visible and infrared videos of the environment near the pipeline, which can be transmitted in real-time to the command center. In the event of an emergency, these videos will help facilitate remote guidance and evacuation of ground personnel.

Additionally, the CW-25E can be installed with an oblique camera, LiDAR system, and other equipment for various tasks. Li Wei explained that this provides technical assurance for the company to deepen its application of UAVs in the future. With these versatile features, the company can avoid repeating investments in the UAV platform and instead focus on developing new application solutions.

Intelligent identification of pipeline risks

JoCloud's AI and image vision technology have played a crucial role in streamlining the IMWNGC drone team's data analysis process. By automatically analyzing the massive amount of drone inspection data and identifying potential risks, the technology has significantly reduced the workload of manual data analysis and improved data processing efficiency.

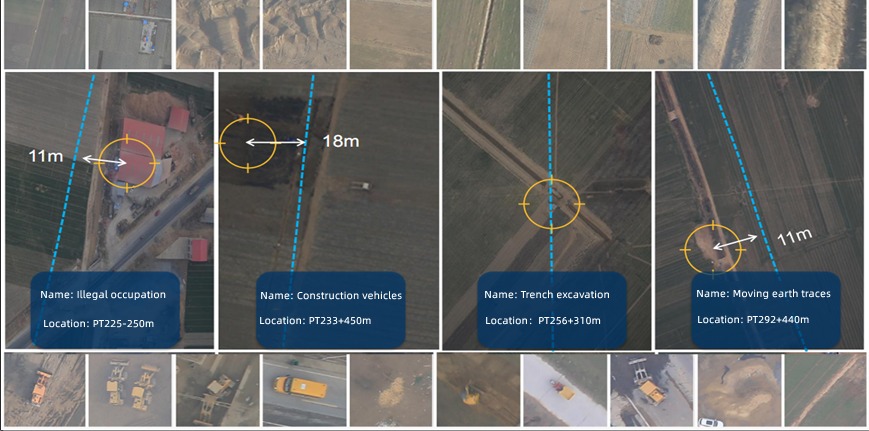

JoCloud's Intelligent Identification of Pipeline Risks

During inspections, the drone collects data on various hidden dangers, which adds to the sample database and enhances potential risk identification. The system can presently identify up to 120,000 pipeline samples with an accuracy rate of over 90%, which includes identifying engineering vehicles, illegal occupation, illegal construction, natural collapse, mounding and filling, and flood damage. Additionally, the system can be tailored to meet the user's specific needs to identify certain items.

To date, JoCloud has identified up to 120,000 pipeline samples.

High-consequence area delineation and control

The JoCloud platform not only detects possible security risks but also allows for buffer zone analysis using GIS technology to establish high-consequence zone boundaries and levels. By following identification guidelines and a judgment model, the platform helped IMWNGC determine the extent of high-consequence areas. This, in turn, enables the development of effective risk control measures to ensure pipeline operations stay within safe levels. Through continuous improvement of adverse impact factors, the platform helps keep the risk levels in check.

High-consequence area 1 - Hohhot, Inner Mongolia Autonomous Region

Pipeline information management system

By using JoCloud, the IMWNGC drone team can manage all their drones, personnel, equipment, mission status, and flight data in one place. They can even mark important targets for inspection and share them with other members through social media and SMS. This enables team members to make timely decisions and quickly deploy their resources.

When the flights are completed, the team uses JoCloud to easily browse and centrally manage all the data collected, including pictures, orthophotos, 3D realistic models, etc.

Eric explained: "Once we have a complete UAV pipeline inspection system, we will be able to model all the geographic information data along the pipeline in 3D. We will then combine the online monitoring sensor data collected along the pipeline with the 3D model to create a 3D visualized pipeline information management system".

The future

Inner Mongolia Western Gas Co., Ltd. is currently focused on exploring and establishing an operational model and management system for large-scale drone pipeline inspection. To fully replace manual inspections with UAV inspections, they are focusing on training more ground inspectors to become UAV flight operators and investing in more drones to increase their fleet.

They are also considering using JOUAV's LiDAR and oblique photography solutions to conduct accurate aerial mapping of key pipeline facilities and geological hazard-prone areas. This will provide accurate geographic information to support the development of pipeline safety emergency plans and on-site disposal in case of accidents.