Road Construction: Design, Material, and Process

Did you know that the total length of paved roads across the globe stretches over 60 million kilometers (almost 37 million miles)?

That's enough to circle the Earth over 70 times! This vast network, constantly under construction, expansion, and repair, is the lifeblood of our modern world.

Road construction is the process of creating, improving, and maintaining the roads that we rely on every day.

It encompasses a wide range of projects, from building entirely new roadways to expanding existing ones to accommodate increased traffic flow.

But perhaps the most familiar type of road construction is repaving, the process of resurfacing worn-out roads to ensure a smooth and safe driving experience.

Importance of Road Construction

But the true significance of road construction transcends the convenience of a pothole-free drive. It's the very foundation of a thriving society.

These roads act as the circulatory system of our world, facilitating the efficient movement of goods and people.

They connect communities, allowing businesses to flourish and fostering a sense of shared identity.

Well-maintained roads become economic engines, enabling the transportation of raw materials, manufactured products, and agricultural goods, propelling growth and development.

The Road Construction Process

The process of transforming a blank canvas of land into a smooth, functional road involves a meticulously planned and highly orchestrated sequence of steps.

Phase 1: Planning (4-6 months)

Before a single shovel breaks ground, extensive planning lays the groundwork for a successful road construction project. This multifaceted phase, typically lasting 4-6 months, encompasses:

- Site Evaluation (2-4 weeks): A geotechnical engineer meticulously assesses the designated area, conducting soil borings and core samples to analyze existing soil composition (clay content, bearing capacity). Environmental assessments are also conducted to identify potential concerns like wetlands or endangered species habitats. Future development possibilities in the area are factored into the planning stage.

- Design Development (4-8 weeks): Traffic volume projections are obtained from state or local transportation departments. These projections, along with terrain features (hills, slopes) and drainage needs, are factored into the design using specialized software. The design engineer creates a detailed blueprint that ensures a safe and efficient road layout, incorporating elements like lane widths, shoulders, sidewalks (if applicable), and proper turning radii at intersections.

- Logistics and Scheduling (2-4 weeks): Securing the necessary equipment, labor, and subcontractors is crucial for smooth project execution. Construction companies solicit bids from equipment rental companies and qualified subcontractors specializing in specific tasks like drainage or bridge construction. Permitting with local and state agencies is finalized during this vital planning stage. Budgetary considerations are also addressed, with cost estimates created based on material quantities, labor hours, and equipment needs.

Planning Phase Technology: Computer-aided design (CAD) software is extensively used to create detailed road designs, including 3D models that allow for virtual visualization of the finished project. Geographic Information Systems (GIS) are employed to analyze aerial photography and existing infrastructure data to inform the design process.

Phase 2: Design (2-4 weeks)

With the groundwork laid, Phase 2 focuses on transforming the conceptual design into a detailed blueprint. Cutting-edge technologies like GPS and laser surveys are often employed to ensure precise measurements and optimal road alignment. Here's a closer look at the factors influencing road construction design:

- Location and Terrain (slope, soil composition): The surrounding environment plays a crucial role in determining road design elements. Steep slopes may necessitate switchbacks or retaining walls, while weak soil conditions may require additional subgrade stabilization techniques.

- Traffic Volume and Composition (cars, trucks, buses): The anticipated number and type of vehicles using the road heavily influence the thickness and composition of the road surface. High-traffic roads with a significant number of trucks will require a thicker, more robust pavement structure.

- Future Development: The design considers potential future growth in the area to ensure the road can accommodate evolving traffic patterns. Provisions may be made for additional lanes or wider shoulders to anticipate increased traffic volume.

- Environmental Impact: Minimizing environmental disturbances during construction and the road's long-term impact are key considerations during the design phase. Erosion control measures and stormwater management systems are incorporated into the design to protect nearby waterways and habitats.

Phase 3: Earthworks (2-6 months)

Now it's time to translate the design into reality! Phase 3 focuses on preparing the designated site for construction, typically lasting 2-6 months depending on the project's complexity. Here's a breakdown of the key activities:

- Site Clearing (1-2 weeks): Vegetation, trees, and debris are removed using large bulldozers or excavators. Some materials may be recycled for use as mulch or chipped for use in erosion control measures.

- Cut and Fill (2-4 weeks): This crucial step involves precisely grading the land through a process called "cut and fill." Motor graders wyposażone (equipped) with GPS technology meticulously scrape away excess soil from high points (cut) and use it to fill in low areas (fill) to establish a stable foundation for the road.

- Grading and Compacting (1-2 weeks): Once the subgrade is shaped, heavy machinery like vibratory rollers compacts the soil to ensure a solid base for subsequent layers. The specific type of roller used depends on the soil composition and desired level of compaction.

- Excavation (1-4 weeks): This vital process involves removing topsoil and vegetation to reach the desired "formation level" where the road will be built. Bulldozers or tractor shovels are commonly used for initial excavation. After reaching the designated depth, a geotechnical engineer or technician inspects the subgrade to assess its strength. If the soil is deemed unstable, stabilization measures like adding crushed rock or geotextiles (fabric for reinforcing soil) may be implemented.

- Hauling and Placement (1-2 weeks): Soil or rock removed during excavation is transported by dump trucks to designated areas for either creating a level surface or constructing embankments (sloped sides of the road). Large compactors ensure proper compaction of the placed material to create a stable foundation.

Phase 4: Aggregate (1-2 weeks)

With a solid foundation established, Phase 4 focuses on creating a strong and stable base for the road surface. This involves laying a layer of aggregate, typically crushed rock or recycled materials, over the compacted subgrade. The specific type and size of aggregate used depends on the design specifications and traffic load requirements. Here's a breakdown of the process:

- Aggregate Spreading (1-2 days): Dump trucks deliver crushed rock onto the subgrade. Motor graders equipped with a long blade and a spreader attachment precisely distribute the aggregate into an even layer.

- Compaction (1-2 days): Heavy vibratory rollers meticulously compact the aggregate layer to achieve the required density and ensure a solid base for the pavement.

Phase 5: Paving (1-4 weeks)

The most visible stage of road construction is paving. The pavement rests on the prepared subgrade and aggregate base, distributing the weight of vehicles to prevent damage to the underlying layers. A well-constructed pavement provides a smooth, safe, and durable driving surface.

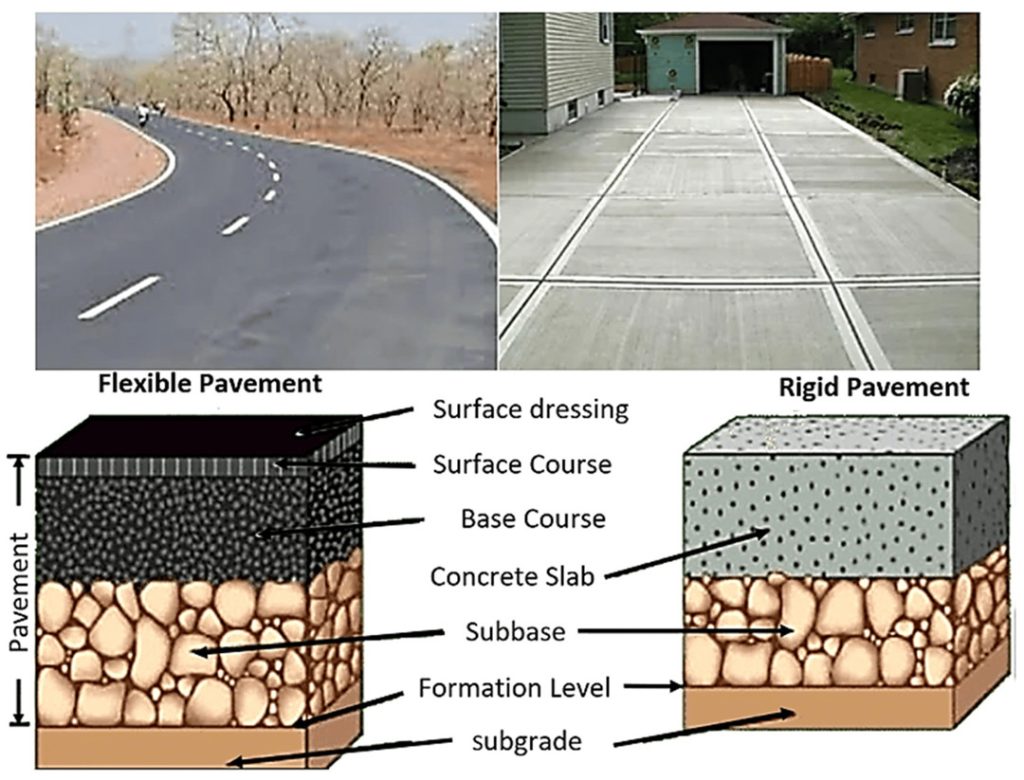

There are two main types of pavement used in road construction:

Image credit: mdpi.com

Flexible Pavements

These multi-layered pavements, often featuring asphalt concrete as the surface layer, are the most common type due to their lower initial cost and relative ease of repair. They offer flexibility to adapt to ground movement caused by freeze-thaw cycles or minor settling.

Asphalt Paving: This process typically involves multiple base layers as well as the main surface course. A flexible asphalt paving project will generally involve these layers:

- Subgrade: Usually a mixture of gravel and sand or dry lean concrete (DLC). It's often called the frost protection layer for its ability to minimize the effects of freezing and thawing cycles in cold climates.

- Base: The middle layer, also known as the binder. It consists of large aggregate mixed with oil to add strength and stability to the pavement structure.

- Surface Asphalt: The top layer is made up of smaller aggregate, sand, and oil-based bitumen which binds everything together. This mixture also creates the qualities that make asphalt roads dark black, smooth, and shiny.

Asphalt paving involves the following steps:

The hot asphalt mix is delivered by insulated dump trucks and spread by a paver. The paver lays down the asphalt at a precise width and thickness. Immediately following, a team of rollers compacts the asphalt in multiple passes to achieve optimal density and smoothness.

Rigid Pavements

These typically consist of a single layer of reinforced or unreinforced concrete. kl Concrete pavements excel in high-traffic areas due to their exceptional durability and long lifespan (often exceeding 30 years). However, they are more expensive to install and repair than flexible pavements.

Concrete Paving: A rigid paving project is similar to asphalt paving, with the addition of the following layer:

- Anti-friction membrane: Placed on top of the base course, it's usually made of polythene sheeting that reduces friction between the concrete slab and the underlying layers. This membrane also helps prevent moisture infiltration into the subgrade.

- Insitu concrete slab: Prepared on-site using mixers and pavers, this layer goes on top of the membrane to add extra strength and rigidity to the pavement structure. The final layer (usually asphalt) goes on top of the concrete slab to provide a smooth driving surface.

Concrete paving involves the following steps:

This method involves a more complex process using a paving machine, a slipform paver, and a tining machine. Concrete is delivered by ready-mix trucks and precisely placed by the paving machine. A curing compound is applied to prevent the concrete from drying too quickly and cracking. Grooves are created on the surface to improve traction and drainage. Once cured, saw cuts are made at regular intervals to create expansion joints that allow the concrete to expand and contract with temperature changes.

Phase 6: Quality Control

After paving is complete, a series of quality control checks are performed to ensure the road meets the design specifications and safety standards. These checks may include:

- Drainage testing: Ensures proper water drainage to prevent pooling and potential road damage.

- Surface smoothness testing: Verifies a smooth and even driving surface for optimal comfort and safety.

- Pavement core sampling: Involves extracting cylindrical core samples from the pavement to analyze its thickness, density, and composition. This ensures the pavement meets the required structural integrity for its intended traffic load.

- Pavement marking: Once quality control checks are passed, permanent lane markings, crosswalks, and signage are applied to guide traffic flow and ensure safety.

How Drones Help Save Time and Money in Road Construction?

Drones are transforming the way roads are built, offering a range of benefits with quantifiable improvements in efficiency, safety, and data collection throughout the construction process.

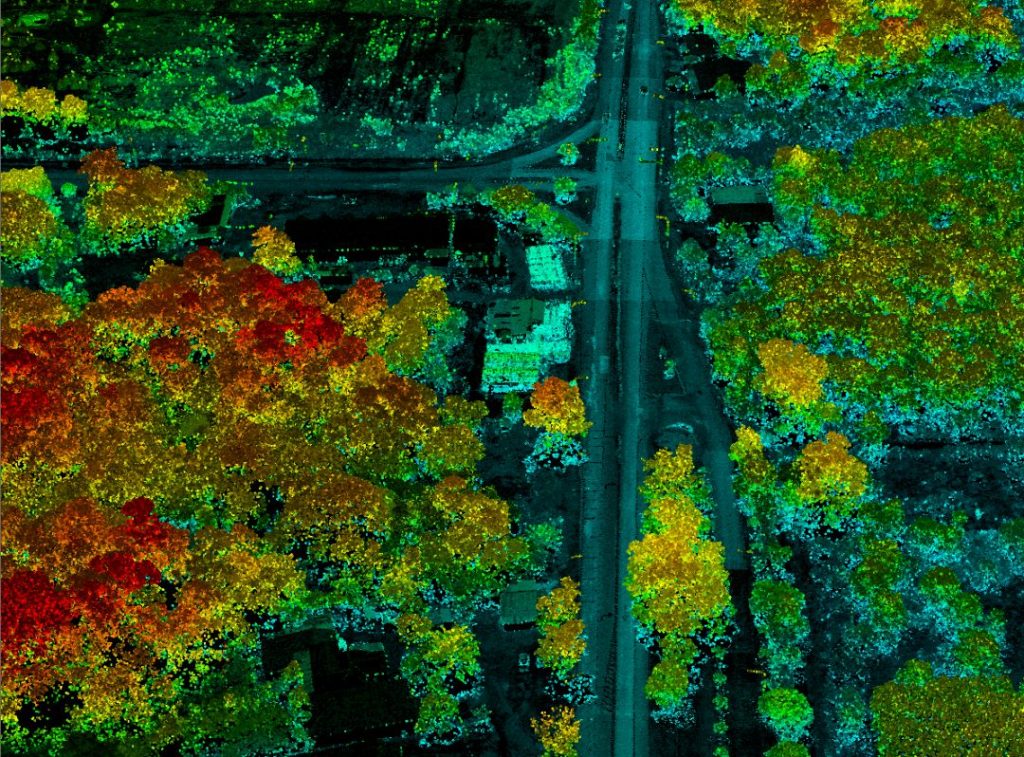

Enhanced Surveying and Mapping

Traditional ground surveying methods can be time-consuming, labor-intensive, and potentially disruptive to ongoing construction activities. Construction drones equipped with high-resolution cameras can capture vast swathes of a construction site in a single flight.

- Data Collection Speed: Drones can capture aerial imagery and LiDAR data of large areas (up to several hundred acres) in a single flight, significantly faster than traditional methods that involve surveyors meticulously traversing the land on foot. Advanced drones like JOUAV's PH-20 can collect data for a 700-acre site in as little as 70 minutes compared to several days required by traditional methods.

- Improved Accuracy: LiDAR technology offers sub-centimeter (less than 0.4 inches) accuracy in elevation measurements, providing highly precise data for creating detailed 3D models of the terrain. This level of accuracy is crucial for planning earthwork activities, such as cut and fill calculations, to ensure optimal use of materials and minimize environmental impact.

- Reduced Costs: The time and labor savings associated with drone-based surveying translate to significant cost reductions for construction companies. For instance, a recent customer reported that using JOUAV's PH-20 drone for surveying resulted in cost savings of up to 30% compared to traditional methods on their large project.

Improved Site Monitoring and Progress Tracking

Gone are the days of relying solely on ground-level observations for tracking construction progress. Regular drone flights provide a comprehensive bird's-eye view of the entire site, offering valuable insights for project managers:

- Remote Monitoring: Drones equipped with high-resolution cameras can be flown at regular intervals to capture visual data of the construction site. This allows project managers to remotely monitor progress, identify areas that may require adjustments, and pinpoint potential delays before they escalate.

- 3D Model Comparison: By comparing current drone footage with the 3D models created during the planning phase, engineers can ensure the project adheres to the design specifications. This proactive approach helps identify and address deviations early on, preventing costly rework later in the project.

- Enhanced Communication: Drone-captured aerial footage can be easily shared with all stakeholders involved in the project, including engineers, contractors, government agencies, and even investors. This fosters improved communication, collaboration, and decision-making throughout the construction process.

Material Stockpile Measurement

Accurately calculating the volume of stockpiled materials like gravel, sand, or asphalt is crucial for effective inventory management and material ordering. Traditionally, this involved manual surveying methods that were time-consuming and prone to errors.

Drones equipped with specialized software can capture high-resolution aerial images of stockpiles. This software then analyzes the images to generate accurate volume measurements of the stockpiled materials.

This data allows for real-time inventory tracking, enabling contractors to optimize material ordering and avoid costly delays due to material shortages.

A study by the Department of Transportation in Oregon found that drone-based stockpile measurement reduced inventory management errors by up to 20%.

Safety Inspection and Hazard Detection

Construction sites can be inherently dangerous environments, with steep slopes, heavy machinery, and exposed electrical wires posing potential risks to workers. Drones can be deployed to:

- Minimize Worker Risk: Drones can be flown to inspect hard-to-reach areas or steep slopes, eliminating the need for workers to put themselves at risk by scaling these areas themselves. This reduces the potential for falls and other construction-related injuries.

- Proactive Hazard Identification: Drones equipped with thermal imaging cameras can be used to identify potential safety hazards before they become accidents. For example, thermal imaging can detect unstable slopes that could pose a risk of landslides or identify buried utility lines that could be accidentally damaged during excavation.

The Role of Different Players in Road Construction

Building a road is no small feat, and its success hinges on the collaboration of several key players, each with a distinct yet interconnected role:

Government Agencies

- Planning and Funding: Government agencies at the federal, state, and local levels play a pivotal role in initiating and funding road construction projects. They conduct traffic studies to identify areas of need, prioritize projects based on traffic volume and safety concerns, and allocate budgetary resources.

- Environmental Considerations: Government agencies ensure compliance with environmental regulations throughout the construction process. They may require environmental impact assessments, mandate wetland protection measures, and oversee the implementation of erosion control plans.

- Permitting and Oversight: Government agencies establish permitting processes for road construction projects. They review construction plans, ensuring adherence to design standards and safety protocols. Inspectors from these agencies regularly visit construction sites to monitor progress and verify compliance with regulations.

Engineering Firms

- Design and Innovation: Engineering firms translate the vision of a road project into a comprehensive blueprint. They employ civil, geotechnical, and traffic engineers who meticulously design the road layout, considering factors like traffic volume, terrain, and drainage needs. They utilize advanced software to model the road and ensure its stability and safety.

- Material Selection and Specifications: Engineers determine the optimal materials for each stage of construction, from the subgrade base to the pavement surface. They specify the type and thickness of materials required based on traffic load expectations and environmental conditions.

- Construction Supervision: Engineering firms often provide construction management services. They oversee the construction process, ensuring adherence to the design plans and safety protocols. They act as a liaison between the government agencies and the construction companies, addressing any concerns or challenges that may arise during construction.

Contractors and Construction Companies

- Project Execution and Workforce Management: Contractors, often awarded the project through a competitive bidding process, are responsible for the physical execution of the road construction plan. They mobilize and manage the construction workforce, ensuring they have the necessary skills and qualifications for each task. This includes operating heavy machinery, performing earthwork activities, and laying pavements.

- Equipment and Logistics: Construction companies bring together the necessary equipment fleet for the project. This may include bulldozers, excavators, graders, pavers, and a variety of trucks for hauling materials. They meticulously plan logistics to ensure a steady supply of materials and efficient equipment utilization throughout the construction process.

- Quality Control and Safety: Contractors are responsible for implementing stringent quality control measures at every stage of construction. This involves testing materials, ensuring proper compaction of layers, and verifying that the finished road meets the design specifications. Safety is paramount, and contractors establish and enforce safety protocols to minimize risks for workers and the public.

FAQs

What Are the Various Flexible Pavement Design Methods?

There are several design methods for flexible pavements (asphalt concrete), each with its own strengths and weaknesses:

- Empirical Methods: These rely on historical data and experience to determine pavement thickness based on factors like traffic volume, expected lifespan, and subgrade strength. They offer a simpler approach but may not be as accurate for complex projects.

- Mechanistic-Empirical (ME) Design: This method utilizes computer software that considers traffic loads, material properties, environmental factors, and pavement response to stresses and strains. It offers a more sophisticated and site-specific approach but requires specialized software and expertise.

What is the Best Material for Road Construction?

There's no single "best" material, as the optimal choice depends on the specific project. Here's a breakdown of the two main options:

- Asphalt Concrete (Asphalt): A popular choice due to its flexibility, affordability, and ease of repair. It performs well in moderate climates but can become brittle in extreme cold.

- Concrete: Offers superior durability in all weather conditions and is often used for high-traffic highways and bridges. However, it's generally more expensive to install initially than asphalt.

How Long Does it Take to Build a Highway?

The timeframe can vary greatly. A simple rural highway might take 1-2 years, while a complex urban project with bridges and interchanges could take 5-10 years or more.

What Are the Grooves in the Road Called?

Those are called transverse tines or grooves. They improve traction, especially in wet weather, and reduce tire noise.

What is Camber in Road?

Camber in roads is the slight slope built into the road surface, making it higher in the middle and sloping down to the edges. This design helps water run off to the sides, preventing puddles and reducing the risk of hydroplaning, which makes driving safer. It also helps keep the road in better shape for longer by preventing water damage. So, basically, camber helps with drainage, safety, and road durability.

What is Berm in Road Construction?

A berm is a raised shoulder along the edge of the road. It can provide additional support for the road and a wider emergency lane. Acts as a physical barrier between the travel lane and the surrounding terrain, it is often used in rural areas for drainage and erosion control.

What is the Road Base Made of?

The base course is typically constructed from:

- Crushed Rock: Crushed stone of various sizes provides a strong and stable foundation for the pavement.

- Recycled Materials: Crushed concrete or asphalt from previous construction projects can be a cost-effective and eco-friendly alternative.

- Soil Cement: A mixture of soil and Portland cement creates a stabilized base layer in some applications.

The specific material chosen for the base course depends on factors like traffic load, subgrade conditions, and local availability of materials.

What is Bituminous Pavement?

Bituminous pavement is another term for asphalt concrete. The word "bituminous" refers to the binder used in the pavement, which is asphalt cement derived from bitumen, a component of crude oil.

Why Bitumen is Used in Road Construction?

Bitumen offers several advantages for road construction:

- Binding Properties: Asphalt cement acts as a strong adhesive that binds together the sand, gravel, and crushed rock aggregate in the pavement, creating a durable and flexible surface.

- Water Resistance: Asphalt is relatively waterproof, protecting the underlying layers from water infiltration that could weaken the road structure.

- Workability: Asphalt can be mixed, transported, and laid at relatively lower temperatures compared to concrete, making it easier to work with in various weather conditions.

- Relatively Lower Cost: Asphalt is generally less expensive than concrete for initial installation, making it a cost-effective option for many road projects.

How Does the Construction of Rural Roads Differ from that of City Streets?

There are some key differences in constructing rural roads compared to city streets:

- Traffic Volume and Weight: Rural roads typically experience lower traffic volume and lighter weight loads compared to busy city streets. This might influence the chosen pavement type (asphalt vs. concrete) and thickness.

- Right-of-Way: Acquiring right-of-way (land needed for construction) can be easier in rural areas compared to densely populated urban areas.

- Drainage Needs: Rural roads might require more extensive drainage systems to handle larger volumes of rainwater runoff from surrounding fields.

- Utilities: Urban streets typically have more underground utilities (power lines, water pipes, etc.) that need to be identified and protected during construction, adding complexity.

- Aesthetics: City streets might incorporate aesthetic considerations like sidewalks, landscaping, and decorative features alongside the functional road structure.

How to Check Road Construction Status?

There are a few ways to check the status of a road construction project:

- Government Websites: Many government transportation agencies maintain websites with information on ongoing construction projects, including timelines and potential disruptions.

- News Media: Local news outlets might report on major road construction projects and updates on their progress.

- Traffic Apps: Mobile apps that provide real-time traffic information often include updates on road construction and potential delays.

- Project Signage: Construction sites often have signage with project information, including a contact number for inquiries.

Why Do They Put Oil and Sand on the Road?

During construction, a layer of water mixed with a small amount of oil may be sprayed on unpaved surfaces to suppress dust. This temporary measure helps control dust generation and improve air quality at the construction site.