LiDAR Mapping Malaysian Roads With Vertical Accuracy Down to 5cm

In the tropical regions of Malaysia, landslides and geological hazards are major concerns for residents. The unpredictable weather patterns and natural disasters cause significant damage to property and loss of life. To address these challenges, Malvus Sense Sdn. Bhd., a responsible mapping company, took up the challenge of providing early warning and protection of vulnerable sections of roads using JOUAV CW-25E.

Job Type | Surveying Two Roads |

Location | Malaysia |

Surveyed Area | 150 km2 (37,065 acres) |

Drone | CW-25E |

LiDAR Sensor | JoLiDAR-LR22S |

Vertical Accuracy | 5.51cm |

Number of Flight | 16 |

Time Spent | 10 Days |

Company Overview

Malvus Sense Sdn. Bhd. is a Malaysian-based technology company that was founded by a group of engineers and entrepreneurs with a vision of utilizing breakthrough technologies in business. The company's main focus is on developing intelligent sensor networks that can monitor various aspects of urban life, such as traffic flow, air quality, and energy consumption.

Malvus Sense also provides consulting services to help businesses and governments integrate smart technologies into their operations. The company has been involved in several projects, including the development of a land-based service information system via SMS Gateway, and it has also participated in events such as the Defence Services Asia (DSA) 2022 and National Security (NATSEC) Asia 2022.

Malvus members and JOUAV technical support team with the CW-25E VTOL drone

Challenge

The Malvus team encountered many challenges during the project. One is that the area is tropical, with lots of rain, hot weather, and dense vegetation, which places high demands on the waterproofness of the drones and the penetration of the radar. Second, the risk of border crossing and violation, to avoid the flight process inadvertently may cross the border to trigger unnecessary questions, which requires high stability equipment to ensure the accuracy of flight control.

- Read more: LiDAR vs. Radar

Solution

According to the requirements of map formation, the Malvus team used a CW-25E VTOL drone equipped with JoLiDAR-LR22S for high-precision 3D point cloud data collection, and the obtained data results can analyze the topography, geomorphology, slope, slope direction, and other geological conditions around the two roads in the area.

To ensure the accuracy of the data and legal compliance of the flight, with the assistance of the JOUAV technical support team, Malvus applied for airspace from the Malaysian Sports Aviation Federation (MSAF) and set the flight bandwidth to 1km.

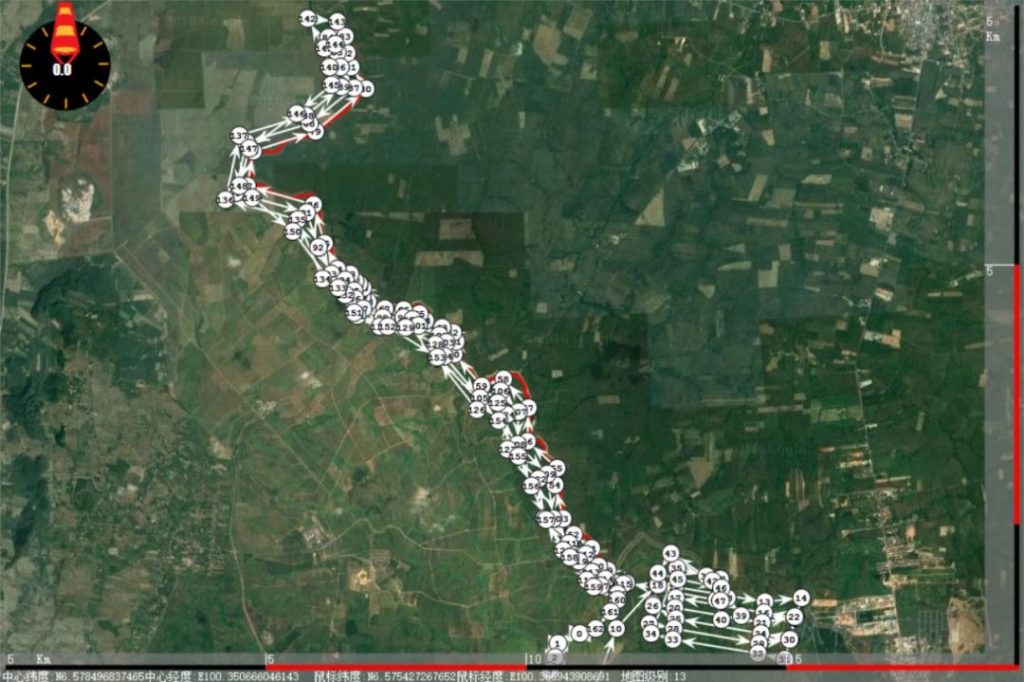

Since it is a border area, the survey area turns are relatively large, Malvus team uses two ways to fly, the first is to use the standard aerial photography route multi-area planning flight. In the area near the borderline, they chose to fly around the border to avoid data loss from the radar sweep and adjusted the route spacing to a smaller distance.

Mission parameters:

- Flight mode: Terrain-follow flight

- Flight bandwidth:1000m

- Relative flight altitude:200m

- Route spacing: 150-200m

- Radar emission frequency: 600KHz

- Average flight time per sortie: 70 minutes

- Average cruising speed: 60km/h

- Overlap percentage:70% front, 50% side

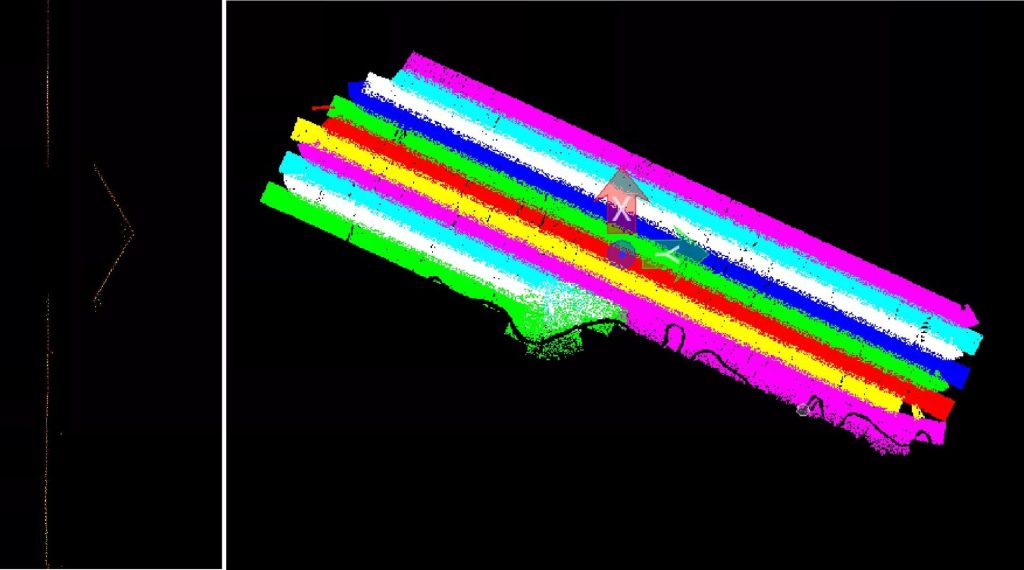

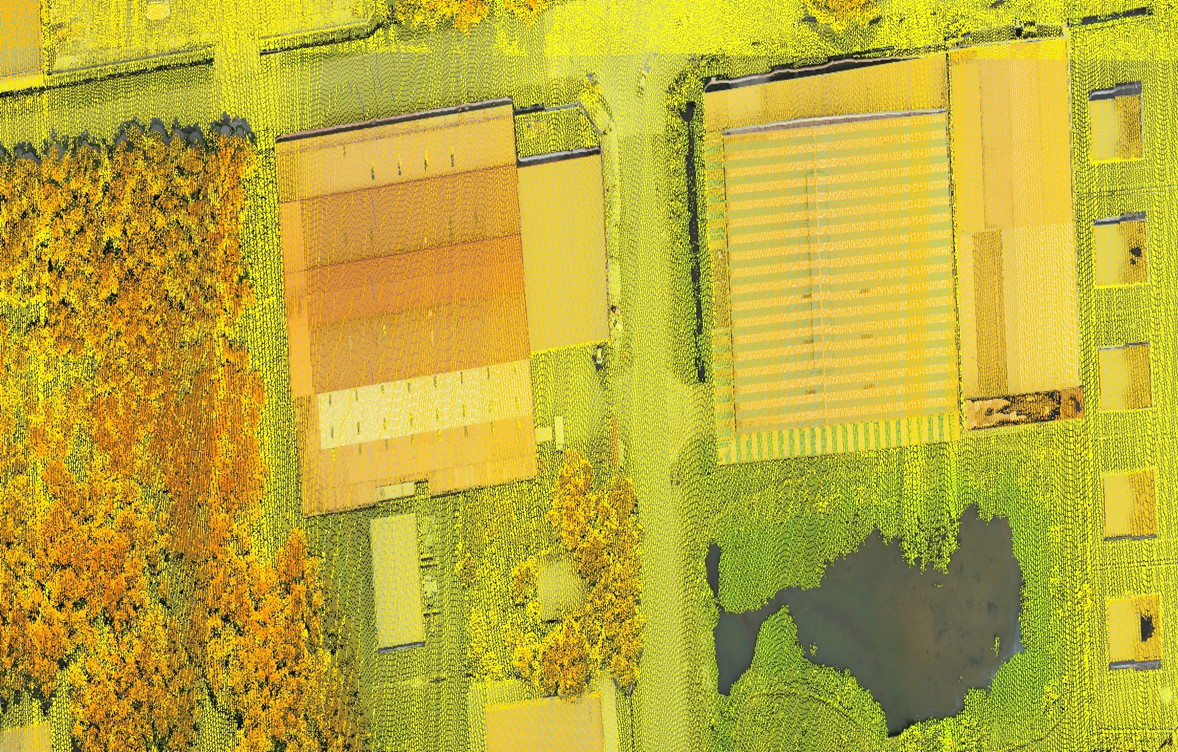

- Single flight strip point density: 23 points/m2

Since it is a border area, the turns of the route in the measurement area are relatively large.

Workflow of LiDAR Mapping

The workflow started with the base station set up by Malvus in the UAV range and a clear line of sight with the drone. The team then conducted a pre-flight inspection to ensure the equipment was properly set up and calibrated. Once the drone was launched, it flies along the predetermined route, while JoLiDAR-LR22S is used to collect point cloud and RGB data simultaneously.

One of Malvus members assemble the CW-25E drone and perform flight inspections with the help of two JOUAV technical support staff

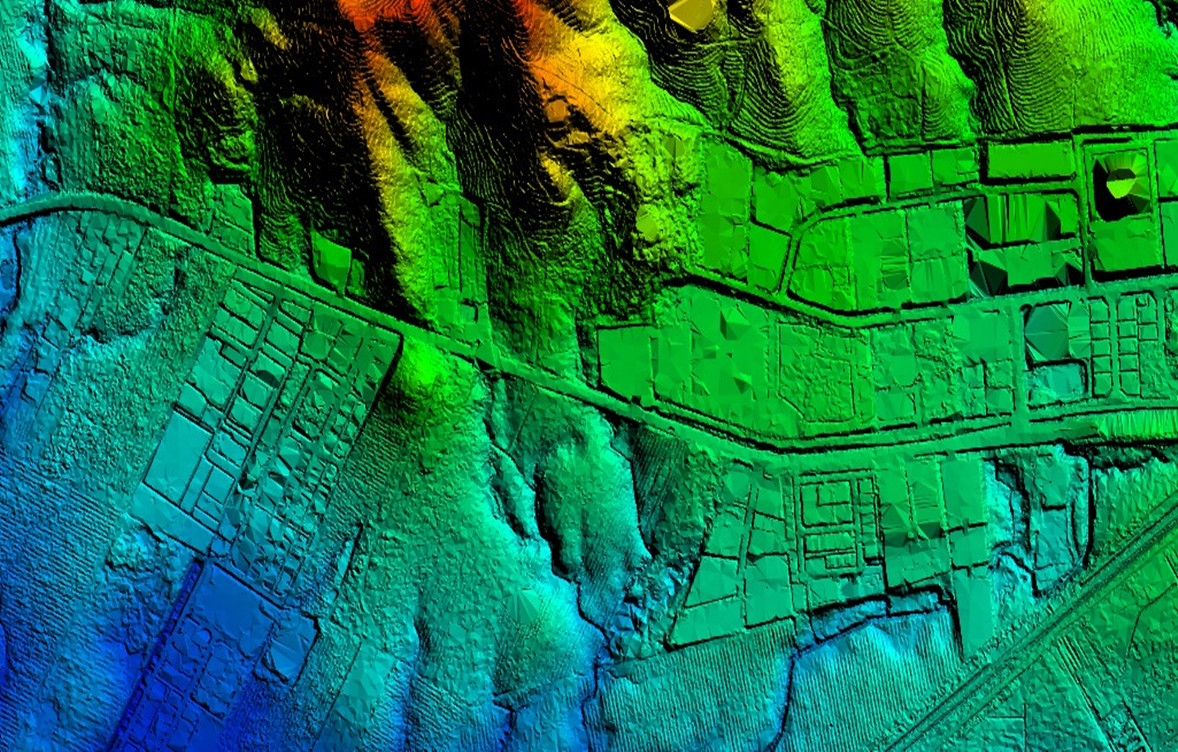

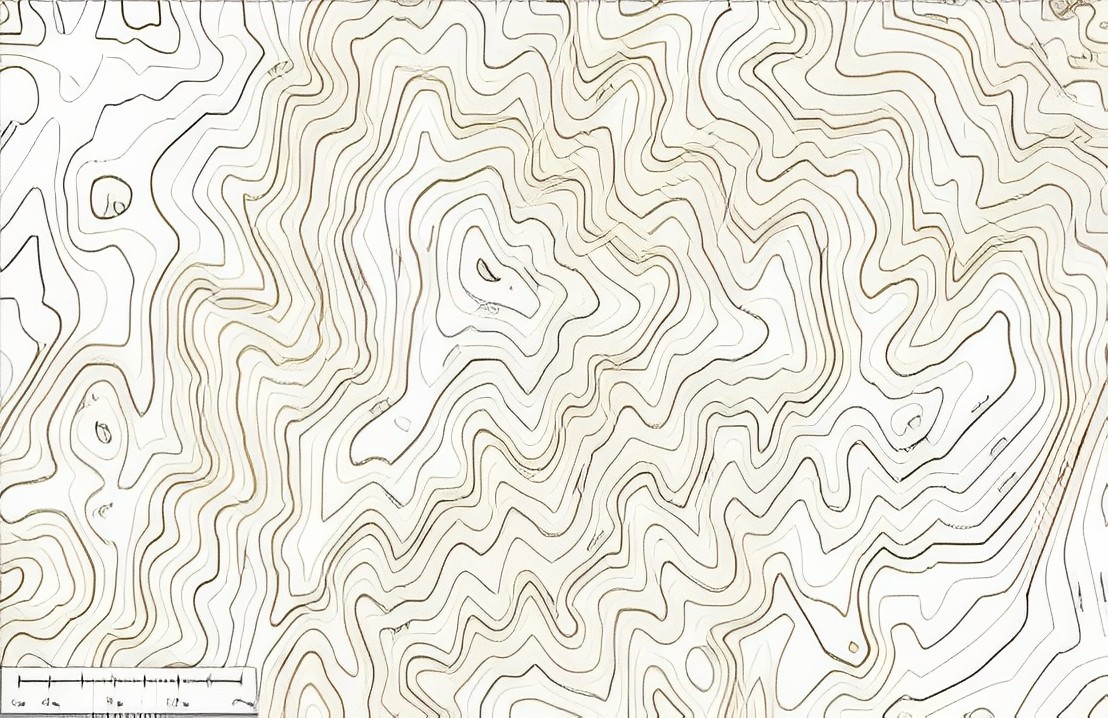

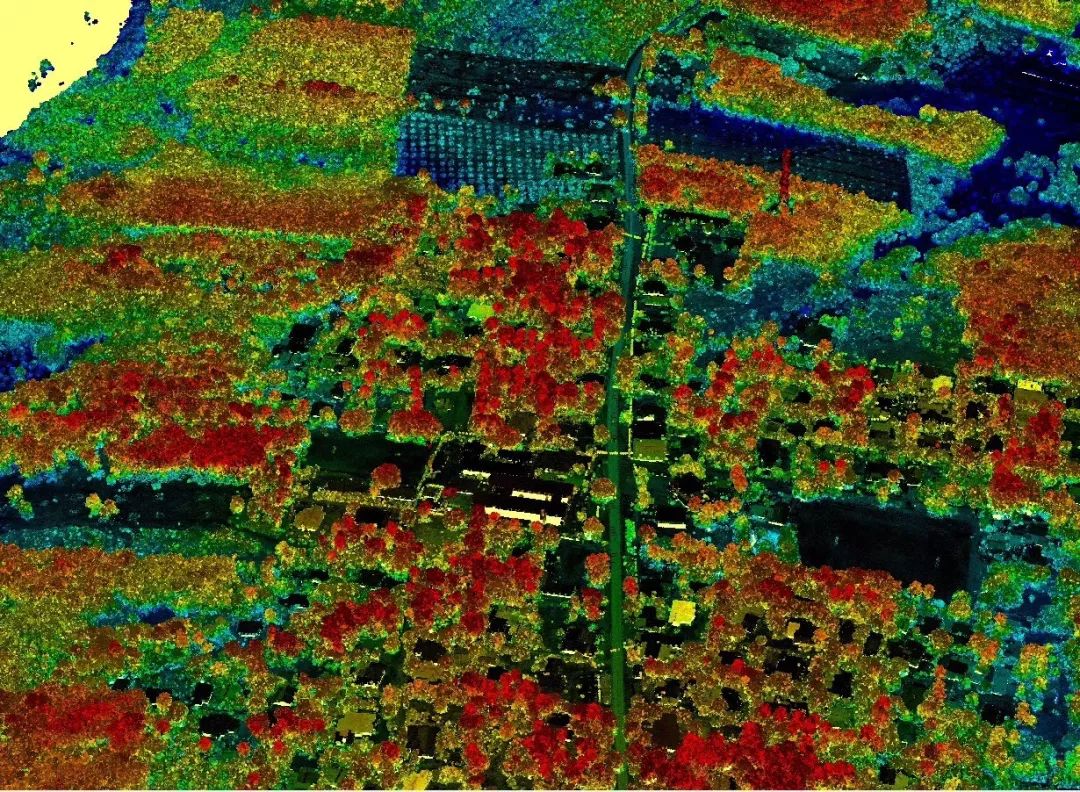

The collected data was then processed and analyzed using JoLiDAR developed by JOUAV. By combining point cloud data with other geospatial data sources such as topographical maps and satellite imagery, the Malvus team created accurate maps and models like Digital Elevation Models (DEMs), Digital Line Graphs (DLGs), Digital orthophoto (DOM). These maps and models showed the topography, vegetation, buildings, and other features of the area with high accuracy.

"We're impressed with JoLiDAR! With this advanced software, the on-site data processing was completed quickly with an export rate of 100MBit/s, and the data download could be completed in a few minutes," said the inspection team leader of Malvus.

JOUAV technical support team members were instructing Malvus members to process data on site

The Malvus team identified vulnerable sections of the roads using the data obtained from the LiDAR mapping. They found that the roads were located on steep slopes with loose soil, making them vulnerable to landslides during heavy rainfall. The team also identified potential locations for landslides and other geological hazards, which could help the authorities to take preventive measures.

The data collected during the mapping operation was shared with local authorities, who used it to improve their disaster management plans. The information was also made available to the public, who could access it through a web portal. This allowed residents and visitors to the area to be aware of potential hazards and take necessary precautions.

Results

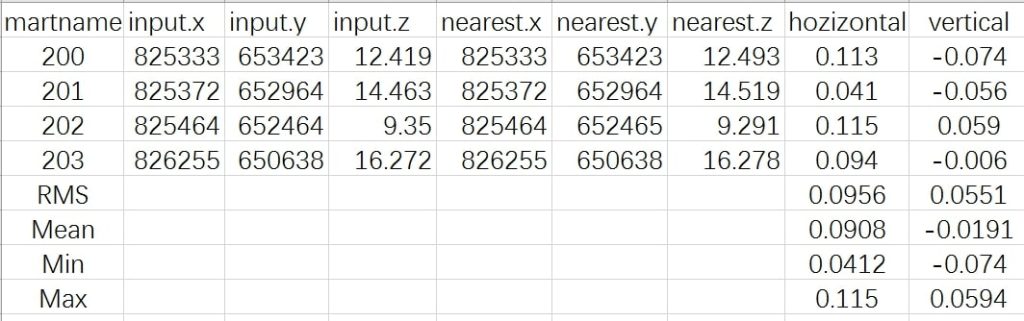

The project was a success. During the 10-day operation of the CW-25E LiDAR drone, the team completed regional operations of 150 square kilometers, achieving the topographic map requirement at a scale of 1:500, which is not possible with traditional aerial survey methods. The team completed operations with a vertical accuracy of only 5.51cm and a DOM with resolutions of 5cm.

"Our team is pleased with the results," said the inspection team leader of Malvus. "The technical support team from JOUAV was instrumental in ensuring the success of the project. Their expertise and guidance helped us overcome the challenges we faced during the project, and we're grateful for their partnership."

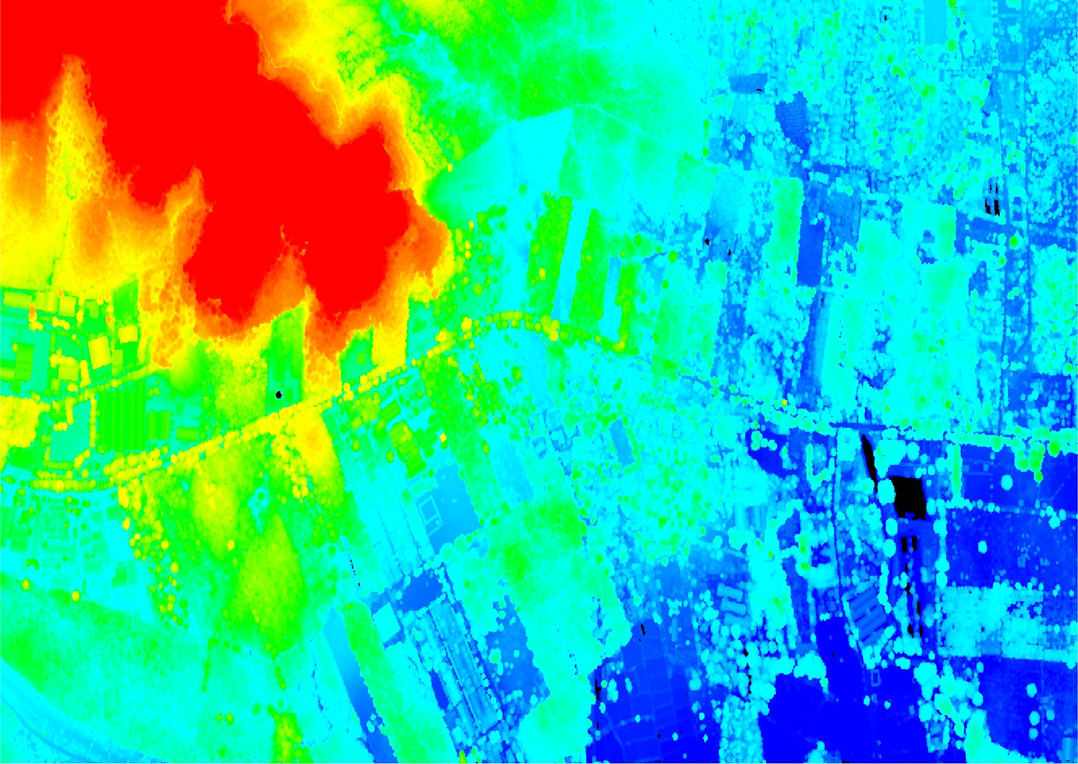

The vertical accuracy of LiDAR point data down to 5.51cm

Good overlap of flight belt, with a density of 23 single strip points/m2

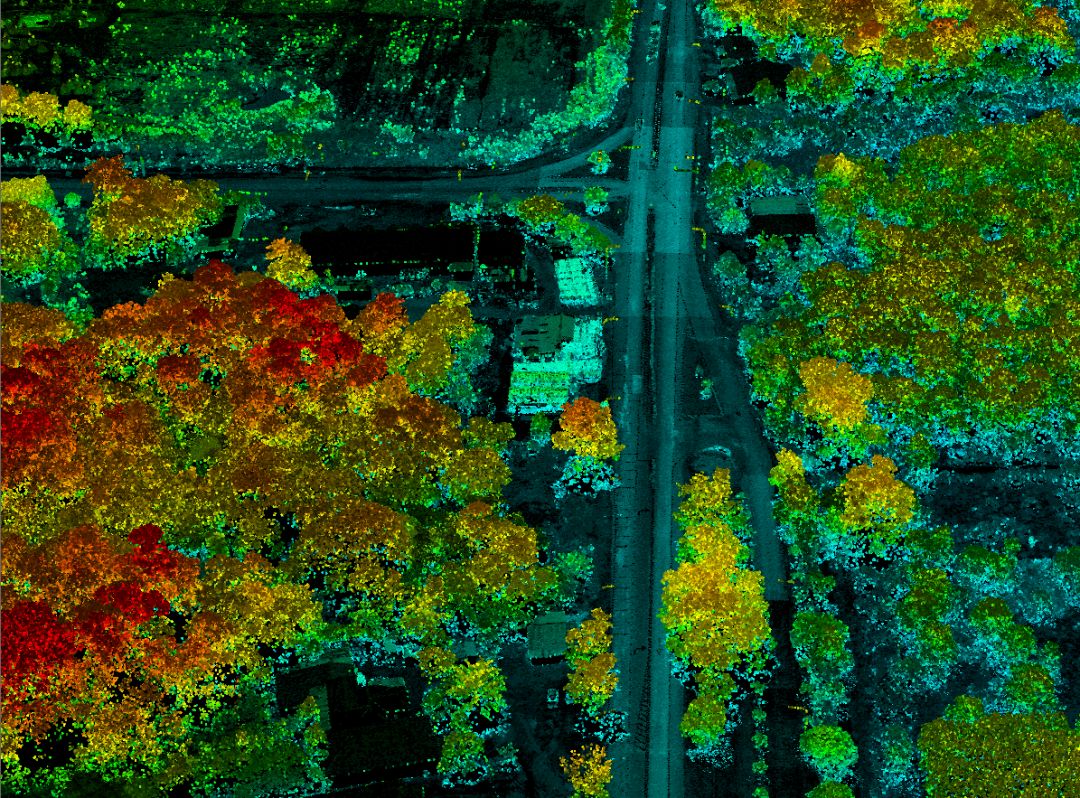

Raw point cloud

True-color point cloud

Digital orthophoto map (DOM)

Digital elevation model (DEM)

Laser+DOM

Digital line graphic (DLG)

Details of the 3D point cloud model

Conclusion

In addition to achieving accurate results in challenging terrain and weather conditions, the JOUAV technical support team also conducted drone science popularization for elementary school children during their stay in Malaysia. "We are proud to not only provide advanced technology solutions but also promote drone education and safety," said Qiang Wang, general manager of the JOUAV technical support team.

JOUAV technical team popularizes drone knowledge to students at school

The successful use of JOUAV CW-25E LiDAR system in the Malaysian surveying and mapping project demonstrated the system's effectiveness in addressing challenging conditions and collecting high-accuracy data in a densely forested operating area. The results highlight the system's reliability, stability, and efficiency, as well as its ability to provide users with a new set of solutions.